Түүхий эд бэлтгэн нийлүүлэлт

Бид 2023 оны 02-р сараас эхлэн “аюулгүй хог хаягдал цуглуулах” чиглэлээр үйл ажиллагаагаа явуулахаар “Эс И Эс Эс Cмарт Солюшн” ХХК охин компаниа байгуулан одоогоор 70 гаран шууд ажлын байр, 3000 гаран шууд бус ажлын байрыг бий болгон үйл ажиллагаагаа өргөжүүлэн ажиллаж байна.

- Хоёрдогч түүхий эдийн үйл ажиллагаа явуулдаг иргэд, ААН-үүдээс Улаанбаатар хотод 3 цэгт буюу БЗД-т амгалан, СХД-т их наран болон үйлдвэрийн дэргэдэх хашаанд, Дархан хотод Хөтөл-Дарханы замд өдөр бүр тасралтгүй хүлээн авч байна.

- Орон нутагт хоёрдогч түүхий эдийн үйл ажиллагаа явуулдаг иргэд, ААН-ийн цуглуулсан хуванцарыг Улаанбаатар хотруу тээвэрлэн хүлээн авч байна.

- Анхны эх үүсвэр дээр ангилан ялгахад олон нийтийн оролцоог бий болгох, нэмэгдүүлэх, хэвшүүлэх замаар СӨХ болон барилга, байгууламжаас ангилсан дахиврыг тээвэрлэн түүхий эдийг бэлтгэж байна.

Үйлдвэрлэл

“Ти Эм Эл Пластик” ХХК үйлдвэр нь европ технологиор өдөрт 75 тонн, жилд 27000 тонн PET тэмдэглэгээтэй ус, ундааны хуванцар савыг дахин боловсруулах хүчин чадалтай ба Монгол Улсын хэмжээнд 1 жилд үүсэх ус, ундааны хуванцар савыг 100% дахин боловсруулах боломжтой.

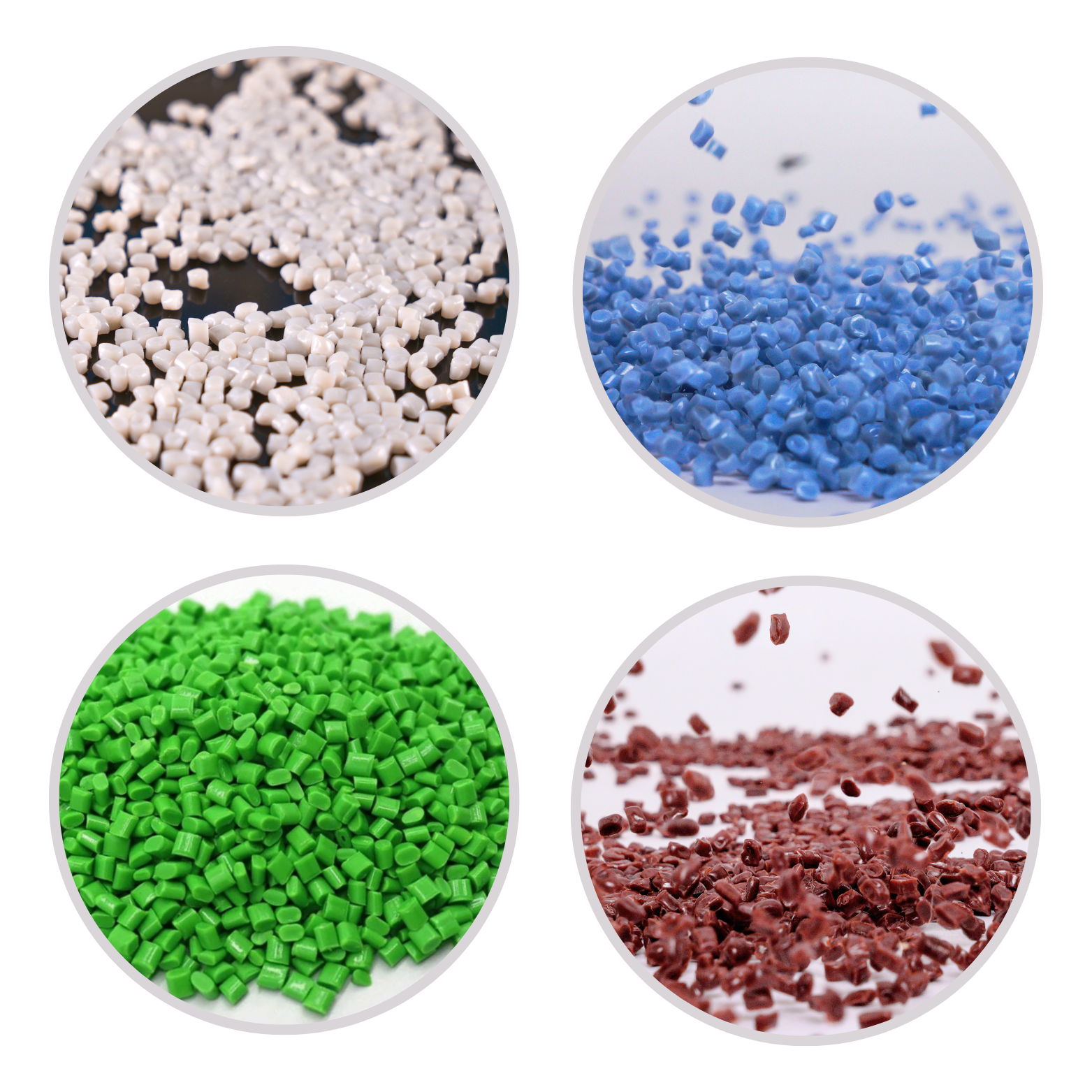

Бид байгальд ээлтэй ногоон үйлдвэрийг бий болгохоор орчин үеийн дэвшилтэт техник технологийг нэвтрүүлэн ажиллаж байна. Үйлдвэрийн үндсэн тоног төхөөрөмж нь Европын холбооны чанарын шаардлага хангасан бүрэн автомат хуванцар хаягдлыг ангилах, хэрчих, угаах, хатаах шугам бүхий Итали улсын Сорема(Sorema), хайлуулах, талстжуулж хөргөх технологи бүхий Америкийн нэгдсэн улсын Хүнс ба эмийн зохицуулах газар болон Европийн хүнсний аюулгүй байдлын газараас хүлээн зөвшөөрөгдсөн Австри улсын Эрема(Erema)брендийн үйлдвэрлэлийн шугамуудыг нэвтрүүлж байгаль орчиинд ээлтэй зах зээлд тэргүүлэгч технологиор савнаас сав үйлдвэрлэх хүнсний дээд зэргийн rpet мөнхлөгийг үйлдвэрлэдэг.

Бид чанар хяналтын тогтолцоог бий болгон эцсийн бүтээгдэхүүний шинж чанарыг илэрхийлэх

• Хайлах температур

• Чийгшил

• Дотоод зууралдлага буюу Intrinsic viscosity

• Өөрийн нягт болон овор хэмжээний нягт

• Органик үлдэгдэл

• Өнгөний координат

• Ацетальдегидийн агууламж

зэрэг нийт 18 төрлийн шинжилгээг 1 цаг тутамд 24 цагийн турш тасралтгүй гүйцэтгэдэг. Үүнээс гадна угаалгад ашиглагдаж буй химийн бодисыг хянах, шахан багласан түүхий эдийн ашигтай материалын хэмжээг тодорхойлох, Сорема үйлдвэрлэлийн шугамын ялгалт чанарын шаардлага хангаж байгаа эсэхийг хянах зэрэг үйлдвэрлэлийн процессын бүхий л шатанд чанарт нөлөөлөх боломжтой бүх параметрүүдийг хянан ажилладаг.

Чанар

Бидний үйлдвэрлэж буй мөхлөг (rPET) нь АНУ-ын FDA, олон улсын GRS, ISO 9001, ISO 14001, FSSC 22000 болон Европын холбооны EFSA чанарын стандартуудын дагуу хүний эрүүл мэнд, хүнсний аюулгүй байдал, бүтээгдэхүүний чанарыг дээд зэргээр хангадаг нь батлагдсан.

Түүхий эд нийлүүлэх боломж

Хэрхэн хамтран ажиллах вэ?

- Худалдан авалтын албатай холбогдох

- Хамтран ажиллах гэрээ байгуулах

- Зориулалтын уут, шуудайг хүлээн авч ялган ангилах ажлыг эхлүүлэх

Ялган ангилахад анхаарах зүйлс:

- Шингэний үлдэгдэлгүй байх

- Овор хэмжээг багасгах

- Савнаас шошгыг салгах

- Дахивар тус бүрээр ангилах

Дахин боловсруулах боломжгүй хуванцар сав:

- Тосны сав

- Сүүн цагаан өнгийн сав

- Хэт бохирдсон сав

- Сүү цагаан идээ хийсэн сав